Amazon Web Services (AWS) is transitioning its data center cooling systems from air-based to liquid-based solutions to support more powerful, heat-intensive AI workloads. Traditional air cooling can’t keep up with the heat generated by densely packed AI chips, prompting AWS to develop a custom liquid cooling system using direct-to-chip cold plates and a closed-loop fluid cycle. This system absorbs heat more efficiently without increasing water use. Designed for flexibility and scalability, the new system is now being rolled out across AWS data centers to meet growing energy and performance demands in an evolving tech landscape. They write:

At its simplest, a data center requires three things to work properly. The first is a building, the kind of thing that can protect the servers from rain, snow, and even tumbleweed. The second is power, the juice that keeps all those servers running.

The third is cooling. This is the element without which those servers could overheat and shut down in a matter of minutes. It’s also the one Amazon Web Services (AWS), and the entire data center industry, is in the midst of transitioning from an air-based to a liquid-based solution.

The shift, happening across parts of the AWS portfolio, matters because there’s actually a fourth thing a data center needs: the ability to evolve. Last year AWS announced it would be rolling out new data center components designed to support the next generation of artificial intelligence innovation and customers’ evolving needs. […]

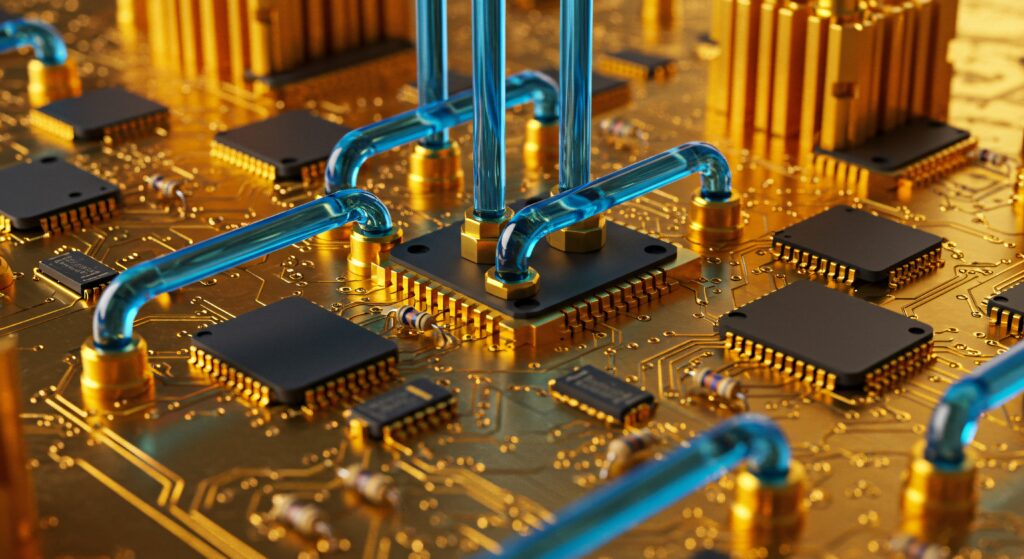

AWS is taking a direct-to-chip approach, which puts a “cold plate” directly on top of the chip. The liquid runs in tubes through that sealed plate, absorbing the heat and carrying it out of the server rack.

From there, it runs to a heat rejection system that cools the liquid (a fluid specifically engineered for this purpose) and then circulates it back to the cold plates. It’s an entirely “closed loop” system, meaning that the liquid continuously recirculates, and—crucially—doesn’t increase the data center’s water consumption. […]

Another key element of the cooling system is the custom coolant distribution unit AWS has developed, which is more powerful and more efficient than its off-the-shelf competitors. “We invented that specifically for our needs,” Klusas says. “By focusing specifically on our problem, we were able to optimize for lower cost, greater efficiency, and higher capacity.” […]

Klusas’s team developed the first example of the system at AWS’s research and development center, a lab where the company tests anything and everything that makes it into its data centers. It then deployed test units in production data centers. Now, the system is ready for use at scale. It will be ramped up this summer to take on more and more of the cooling workload, and start moving into other data centers.

How and where it picks up that work will be determined over time, but Klusas is confident in the system’s ability to adapt for a rapidly evolving future. “We’ve created a system that is very energy and cost efficient,” he says, “and can be deployed precisely where liquid cooling is needed to meet our customers’ demands.”

Read more here.